Germany has long been recognized as one of the global centers of dental technology and precision engineering. From diamond burs and carbide burs to specialized rotary instruments for surgical and restorative procedures, German suppliers are among the most trusted in the world. As dental practices and distributors search for reliable Dental Burs Suppliers, understanding the leaders in Germany’s market becomes essential in making informed purchasing decisions.

As dental treatments become increasingly advanced, clinics and laboratories demand burs that ensure precision, durability, and compatibility with a variety of high-speed and low-speed handpiece systems. In evaluating the top Dental Burs Suppliers, several factors stand out:

High-precision tungsten carbide

Multi-layer diamond coatings

Corrosion-resistant stainless steel

Ultra-fine grit technology

These materials dramatically impact cutting efficiency, heat generation, and lifespan.

Top suppliers maintain micron-level tolerances to ensure smooth rotation, reduced vibration, and greater clinical control.

Germany’s strict regulatory environment ensures high levels of safety, sterilization compatibility, and quality management.

Leading companies typically offer:

Diamond burs

Carbide burs

Surgical and implantology burs

Endodontic access burs

Finishing & polishing burs

Laboratory burs

In 2025, more clinics and distributors are choosing suppliers who offer:

Custom shapes

Private labeling

Bulk manufacturing

Tailored material and coating solutions

Longer-lasting diamond coatings

Burs designed for minimally invasive dentistry

Sustainability-focused medical packaging

High-speed bur designs for CAD/CAM and digital workflows

These trends influence which suppliers remain competitive and future-ready.

Germany has earned a reputation as the “engine of dental manufacturing”—particularly in rotary instruments. Several factors contribute to its leadership:

German companies have decades of experience producing dental rotary tools with exceptional engineering consistency.

Germany exports dental burs worldwide, with strong distribution networks across Europe, North America, and Asia.

German suppliers invest heavily in R&D, supporting advancements in diamond coating processes, wear resistance, specialty designs, and enhanced ergonomics.

With some of the strictest manufacturing standards in Europe, Germany ensures product safety and quality that global buyers value.

These strengths collectively position Germany as one of the most reliable sources for high-quality Dental Burs Suppliers in 2025.

Established in 2012 and headquartered in Tangshan City, Hebei Province, China, Tangshan UMG Medical Instrument Co., Ltd. (UMG) is a premier dental burs supplier and manufacturer specializing in the research, development, production, and global sales of high-quality dental equipment and consumables. As a trusted wholesale dental lab supplies provider, UMG offers an extensive range of products including dental units, simulators, handpieces, and disposable materials, with a strong emphasis on dental burs for precision oral care. Employing 51-200 professionals, the company boasts an annual production capacity exceeding 4,000 dental units and exports to over 50 countries across Europe, Southeast Asia, the USA, Australia, the Middle East, and Africa. UMG's mission is to deliver affordable, customizable solutions that support dental clinics, laboratories, and educational institutions, embodying the belief that caring for teeth is caring for life.

UMG upholds rigorous standards as a reliable dental burs supplier, having passed ISO13485 quality management audits and securing CE, ISO, and FDA certifications to ensure biocompatibility and safety per international standards like ISO 10993. Recognized as an Audited Supplier and Diamond Member on platforms like Made-in-China, the company holds patents for innovative designs and was listed among the Top 10 Dental Burs Manufacturers in 2025. These accolades reflect UMG's commitment to excellence, earning high praise for quality products and responsive customer service from global partners.

With over 10 years of export trade and OEM expertise in wholesale dental equipment, UMG has processed customized dental chairs, simulators, and consumables for clients in Germany, Russia, Mexico, the USA, and beyond. Notable cases include large-scale supplies for oral care professionals in endodontics, implantology, and orthodontics, supporting spot production and mass customization with complete mechanical equipment. This extensive experience has built a reputation for reliable delivery and thoughtful services across diverse dental applications.

UMG's success is driven by a dynamic team of foreign trade elites, creative engineers, and dedicated R&D specialists who foster continuous innovation in dental burs suppliers' offerings. The technical teams focus on advanced CNC manufacturing and unique production processes for products like multi-plating diamond particles, enabling new developments in tungsten carbide and diamond burs. Through independent R&D, UMG updates its portfolio to meet clinical needs, supporting long-term partnerships via OEM/ODM services.

Key products and services:

Dental burs — OEM/wholesale, quality inspection, customization.

Diamond burs — kit assembly, polishing & grinding efficiency testing.

Carbide burs — bulk supply, mechanical strength testing.

Dental handpieces — assembly and after-sales support.

Dental simulators — R&D, OEM/ODM for educational kits.

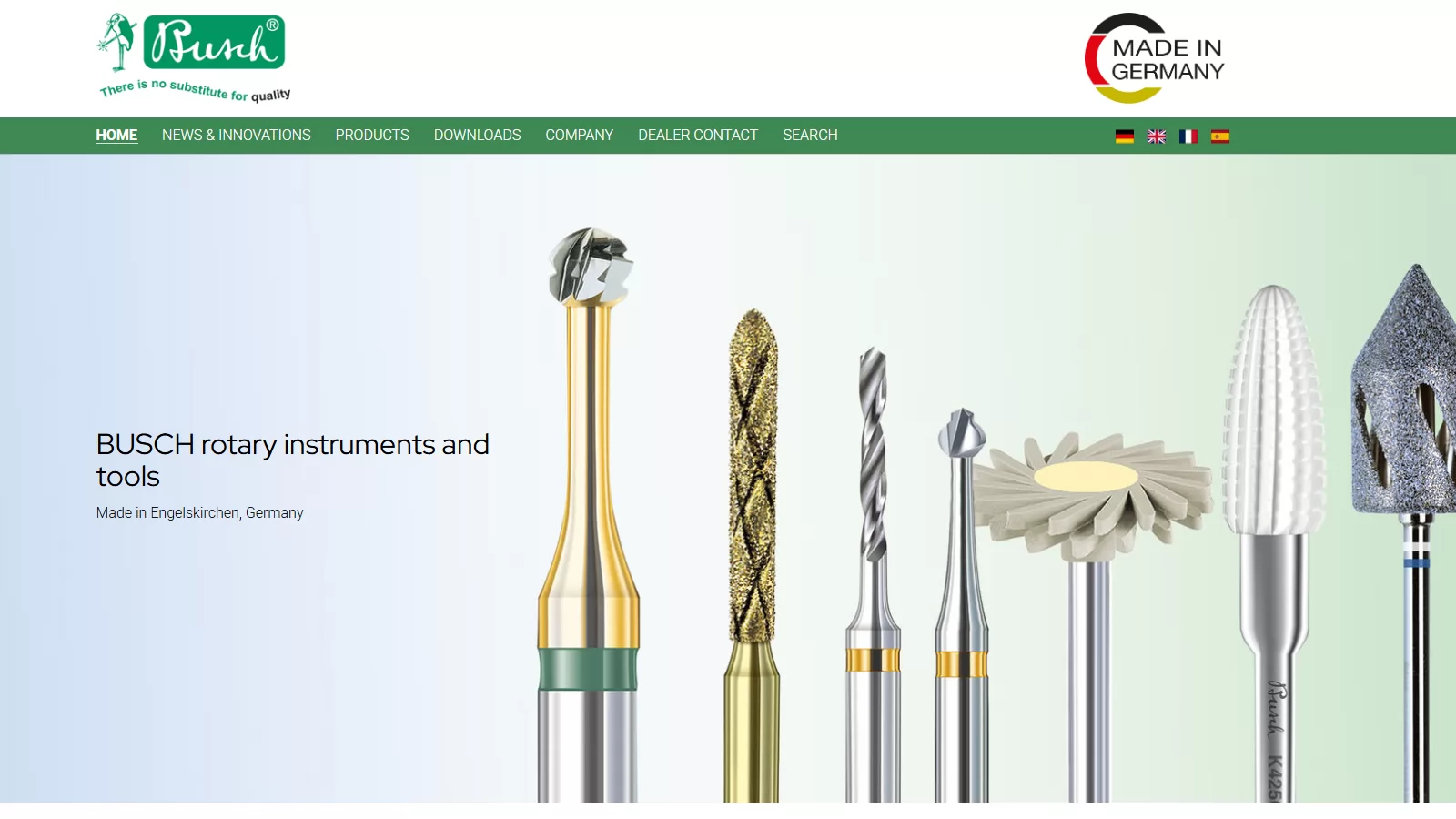

Established in 1905 in Düsseldorf, Germany, by brothers Ernst and Otto Busch, BUSCH & CO. GmbH & Co. KG has evolved into a third-generation family-owned enterprise specializing in rotary precision instruments and tools. Headquartered in Engelskirchen, the company is a premier dental burs suppliers, producing high-quality carbide burs, diamond burs, steel instruments, ceramic cutters, and abrasives entirely in-house to ensure exceptional precision and durability. With a global reach to nearly 100 countries, BUSCH focuses on dentistry and dental technology, extending its expertise to jewelry, podiatry, and nail design applications. As dental burs suppliers, BUSCH emphasizes user-centric solutions that enhance clinical efficiency and patient comfort, drawing on over a century of craftsmanship to deliver tools that withstand high-speed demands.

Certified to ISO 13485 standards for medical device quality management, BUSCH upholds rigorous in-house production protocols that guarantee concentricity and longevity in every dental bur. Pioneering achievements include introducing Germany's first dental carbide burs in the early 20th century, alongside ceramic-bonded abrasives and diamond-coated instruments—innovations that have produced over one billion burs and revolutionized cavity preparation by reducing patient anxiety through superior performance. These milestones have solidified BUSCH's reputation as trusted dental burs suppliers, with products praised by distributors like Pfingst & Company for their premium German engineering and reliability in professional settings.

With 119 years of expertise, BUSCH has shaped modern dentistry from its origins, when Germany had just 500 dentists, to today's high-tech landscape—supplying tools that enable precise excavation, finishing, and surgical procedures. Historical cases highlight how BUSCH's carbide burs facilitated the shift to high-speed handpieces, minimizing treatment times and discomfort in restorative work. Contemporary user experiences, shared via distributors, underscore the burs' role in efficient crown fabrication and minimally invasive decay removal, with clinicians reporting extended tool life and consistent results in daily practices like fissure drilling and root surface smoothing. BUSCH's contributions extend to community support, including aid to organizations like Deutsche Welthungerhilfe, reflecting a commitment to broader societal impact.

BUSCH's dedicated, motivated team of specialists drives continuous advancement, fostering a culture of long-term innovation rooted in tradition and forward-thinking R&D. Key innovations as dental burs suppliers include the Zirkon Workflow Set for seamless zirconia processing, KERA Ceramic Cutters for lightweight acrylic and zirconia work, and COOL DIAMANT instruments with optimized coolant flow for gentle preparations. These developments, alongside tools like the 1SXM Excavating Bur for conservative caries removal, demonstrate BUSCH's focus on precision engineering that preserves tooth structure and enhances procedural safety.

Key product types and services:

carbide burs — precision cutting and finishing for cavity and crown preparation

diamond burs — high-efficiency grinding and contouring of ceramic and natural tooth structure

polishing systems / polishers — finishing, high-gloss polishing and surface refinement

ceramic cutters — shaping and trimming of ceramic restorations and zirconia pre-sintered blocks

zirconia workflow sets — stepwise instruments for pre-sintered zirconia milling, finishing and polishing

Acurata GmbH & Co. KGaA, founded in 1977 by Renate and Georg Mahnhardt in Thurmansbang, Lower Bavaria, Germany, stands as a leading dental burs supplier specializing in high-performance rotary instruments for dental practices, laboratories, CAD/CAM systems, podiatry, and nail care. With over 40 years of expertise, the company manufactures more than 3,000 precision tools in-house, including carbide burs, diamond burs, and polishers, all bearing the "Made in Germany" seal. As a global player, Acurata serves professionals worldwide through a robust sales network, emphasizing quality medical devices that ensure patient safety and environmental protection in dental procedures.

Certified under EN ISO 13485 for medical devices, Acurata upholds stringent standards in development and production, positioning it as a trusted dental burs supplier. A key achievement came in 2005 when it pioneered the expansion into dental CAD/CAM instruments, revolutionizing precision tooling for modern dentistry. The company's in-house processes—from R&D to delivery—have earned international acclaim, with products integrated into oral and maxillofacial surgery worldwide, reflecting its commitment to excellence in dental burs and rotary instruments.

Boasting over four decades of hands-on experience, Acurata has equipped dental professionals with reliable dental burs for diverse applications, from routine cavity preparations to complex CAD/CAM milling. In dental laboratories, its carbide burs and diamond instruments have supported thousands of restorations, enabling efficient workflows and superior outcomes. Case in point: podiatrists and oral surgeons rely on Acurata's surgical burs for precise, low-vibration procedures, as evidenced by consistent adoption in global practices for prophylaxis and orthodontics, reducing procedure times while maintaining accuracy.

Acurata's 22-member team, comprising experts in production, logistics, sales, and administration, fosters a culture of apprenticeship and continuous training in machining and media design. Innovation drives the company forward, with a passion for research yielding future-oriented solutions like multilayered diamond burs for enhanced durability. This innovative edge has expanded Acurata's portfolio into industrial sectors, solidifying its role as a forward-thinking dental burs supplier committed to precision and sustainability.

Best Products:

Carbide Burs: for efficient material removal and cavity preparation in dental restorations

Diamond Burs: for precise grinding and shaping of enamel and composites

Surgical Burs: for accurate bone cutting in oral and maxillofacial procedures

Prophylaxis Instruments: for gentle polishing and cleaning in preventive dental care

CAD/CAM Burs: for high-speed milling of prosthetic frameworks and implants

NTI-Kahla GmbH, a German mid-sized manufacturer founded in 1996 and headquartered in Kahla, Thuringia, specializes in high-quality rotary dental instruments as premier dental burs suppliers. With over 25 years of expertise, the company supports dentists and dental technicians worldwide by producing more than 3,800 precision tools for dental practices, laboratories, and CAD/CAM applications, exporting to over 100 countries. Committed to efficiency and innovation, NTI-Kahla ensures seamless daily workflows through German-engineered dental burs and rotary solutions.

NTI-Kahla holds ISO certifications and EC Certificates for rotary dental instruments, guaranteeing stringent quality standards in production and safety for dental burs suppliers. Key achievements include the inauguration of a state-of-the-art logistics center and global recognition for durable, efficient products that enhance precision in restorative and prosthetic dentistry.

Boasting 25+ years in rotary instrument development, NTI-Kahla has optimized tools for real-world applications, such as zirconia processing and crown preparation, reducing procedure times in clinical settings. While specific case studies highlight improved marginal fit in CAD/CAM hybrid ceramics using their burs, the company's track record underscores reliable performance across thousands of global dental practices.

A dedicated team of competent advisors provides personalized consultations via hotline and WhatsApp, fostering strong partnerships with dental professionals. Innovations like Unimatrix® bonding for uniform diamond placement and Z-Cut technology for ceramic durability exemplify NTI-Kahla's forward-thinking approach as dental burs suppliers, extending tool lifespan and precision.

Best Products:

Diamond Burs: Chamfer preparation and zirconia grinding services with custom grit sizes.

Tungsten Carbide Burs: Crown separation and finishing services for prosthetic materials.

Polishers: Surface refinement services for restorations and implants.

Founded in 1923 by the Brasseler brothers in Lemgo, Germany, Komet Dental has evolved from a modest workshop—initially adapting sewing machines for dental burs production—into a global leader in rotary dental instruments as a family-owned enterprise now in its third generation. Headquartered in Lemgo with manufacturing excellence "Made in Germany," the company serves over 100 countries, including a U.S. expansion in 2007, providing high-quality dental burs, diamonds, and endodontic tools to dentists, lab technicians, endodontists, and oral surgeons worldwide.

Komet Dental upholds rigorous professional qualifications, certified under ISO 13485, EN ISO 13485, ISO 9001, and MDSAP standards for quality management in medical devices, ensuring compliance with EU-MDR and FDA regulations. Achievements include pioneering tungsten-carbide instruments in 1956, diamond burs in 1958, and being the first to launch ceramic burs in 2003, alongside the 2025 Red Dot Design Award for its innovative EnDrive endodontic motor. These milestones underscore Komet's role as a trusted dental burs supplier, setting industry benchmarks for precision and reliability.

With over 100 years of experience, Komet has delivered transformative solutions, such as single-use dental burs reducing cross-contamination in clinical settings—as shared by Dr. Christian Yaste in his long-term adoption story—and the DIAO diamond bur's breakthrough design for smoother debris flushing in restorative cases. These examples highlight efficient workflows in cavity preparation and endodontic treatments across global practices.

Komet's team of in-house engineers, dentists, and R&D specialists collaborates closely with professionals to drive innovation, investing in sustainable technologies like heat-treated files and coarsest Deep Purple diamonds for enhanced durability. This expertise ensures ongoing advancements in dental burs suppliers' offerings.

Key Dental Burs Products and Services:

Tungsten Carbide Burs: Efficient tooth preparation and shaping for restorative dentistry.

Diamond Burs: Precise cutting and cavity preparation with optimal debris management.

Ceramic Burs: Durable finishing and contouring in prosthetic procedures.

Single-Use Diamond Burs: Hygienic, infection-controlled cutting for single-patient enamel reduction.

DENDIA GmbH stands as a premier dental burs supplier, specializing in the development, production, and global distribution of high-quality rotary dental instruments. Founded in 1947 in Vienna, Austria, and relocated to Feldkirch in 2000, the company has evolved into a trusted name among dental burs manufacturers, emphasizing precision-engineered tools that bridge patient comfort and clinical excellence. With a commitment to "the first step to a perfect smile," DENDIA delivers an extensive range of dental burs and related instruments for dentistry and laboratory applications, serving professionals worldwide as a reliable supplier of dental burs for restorative, surgical, and orthodontic procedures.

DENDIA upholds stringent standards as a certified dental burs supplier, holding DIN EN ISO 13485:2016 accreditation for quality management and compliance with the EU Medical Device Directive 93/42/EEC (RL 93/42/EWG). These qualifications underscore its expertise in producing safe, durable dental burs that meet international regulatory demands. Key achievements include the establishment of the iconic "DICA-Diamond" brand in 1951, revolutionizing cavity preparation, and securing patents for innovative designs like Helicoidally Grooved Dental Burs, which enhance cutting efficiency and reduce procedural trauma. As a recognized exhibitor at global events such as AEEDC Dubai, DENDIA continues to affirm its leadership in the dental burs suppliers market.

Boasting over 75 years of hands-on experience, DENDIA excels as a veteran dental burs supplier, with a proven track record in crafting instruments that support diverse clinical workflows. From high-volume restorative practices to specialized labs, its dental burs have facilitated countless successful treatments, including precise enamel reduction and bone contouring. While specific case studies highlight seamless integration in European and international dental networks, the company's longevity—spanning steel, diamond, and carbide innovations—demonstrates reliability in real-world applications, minimizing chair time and maximizing outcomes for endodontists and oral surgeons alike.

DENDIA's dedicated team of engineers and dental specialists drives ongoing innovation in the dental burs suppliers sector, leveraging decades of collective expertise to refine manufacturing processes with modern CNC technology and fine-grain materials. This collaborative approach fosters breakthroughs, such as advanced tungsten carbide formulations for superior longevity in dental burs. Committed to R&D, the team continually evolves product lines, ensuring DENDIA remains at the forefront of rotary dental instruments innovation, adapting to emerging needs in minimally invasive dentistry.

Key Products and Services:

Diamond Burs: Cavity preparation and finishing for restorative dentistry

Carbide Burs: High-speed cutting and shaping in crown and bridge work

Steel Burs: Initial tooth reduction and surgical access

Surgical Burs: Bone cutting and implant site preparation

Polishers and Abrasives: Surface smoothing and contouring services

Shenzhen OVO Medical Instruments Co., Ltd., headquartered in Shenzhen, China, stands as a premier dental burs supplier and professional manufacturer of dental equipment. With decades of experience in the industry, OVO Dental delivers a comprehensive one-stop solution for dental clinics and laboratories worldwide, specializing in high-precision rotary instruments like dental burs for endodontic works, cavity preparation, and tooth shaping. As a renowned dental burs manufacturer, the company emphasizes stable quality, competitive pricing, and customized services to meet diverse needs in dental procedures.

OVO boasts over 95% of its products certified with CE and ISO standards, ensuring compliance with international safety and quality regulations for dental burs suppliers. Ranked #1 among the Top 10 Dental Burs Manufacturers in 2025, the company is recognized for its exceptional service and high-quality diamond burs and tungsten carbide burs that adhere to world-class precision standards. These achievements underscore OVO's commitment to reliability in supplying rotary instruments essential for porcelain cutting, bone shaping, and filling removal.

Drawing on decades of expertise, OVO has supported global dental professionals through tailored solutions for endodontic and restorative procedures. While specific case studies highlight successful implementations in high-volume clinics, the company's track record includes seamless integration of dental burs in diverse surgeries, backed by responsive 24-hour quote services and size guidance based on practitioner feedback.

OVO's technical team, with years of hands-on experience in the dental field, excels in understanding customer demands and fostering sincere collaborations for innovative dental burs solutions. Leveraging advanced production technologies, the team drives ongoing innovation in tungsten carbide burs and diamond burs designs, enhancing durability and efficiency for modern dental practices.

Key Products and Services:

Diamond Burs: Customized size selection for precision cutting in endodontic works

Tungsten Carbide Burs: Application guidance for cavity preparation and bone shaping

Sirona Dental Systems, established in 1877 in Erlangen, Germany, as Reiniger, Gebbert & Schindler (RGS), pioneered dental technology and emerged as a leading dental burs supplier. Originally focused on mechanical engineering for dentistry, it developed groundbreaking tools before being acquired by Siemens in 1925. In 1997, Sirona became an independent entity, Sirona Dental Systems GmbH, specializing in dental equipment, imaging, and instruments. The 2016 merger with DENTSPLY formed Dentsply Sirona, the world's largest manufacturer of professional dental products, with 16,000 employees across 40+ countries and sales in 150+ nations. As a key dental burs supplier, Sirona's heritage drives supplies like carbide burs and diamond burs for global clinics and labs, enhancing precision in restorative and surgical dentistry.

Sirona's qualifications stem from over a century of ISO-certified manufacturing and FDA approvals, ensuring safe, high-performance dental burs. Achievements include inventing the first electric dental drill in 1887 and the CEREC CAD/CAM system in 1985, revolutionizing chairside workflows. As a dental burs supplier, it earned accolades through Dentsply Sirona's 2024 sustainability milestones, such as Newsweek's America's Greenest Companies ranking and Sustainalytics' Top-Rated ESG in healthcare, underscoring commitment to eco-friendly surgical burs and lab burs production.

With 130+ years of expertise, Sirona has powered millions of procedures as a reliable dental burs supplier. Notable cases include the 20-year Global Clinical Case Contest, where students use Sirona's diamond burs for direct/indirect restorations, honoring winners like Sofiia Grindenko in 2025. Over 221,000 professionals have accessed education on carbide burs applications, supporting real-world endo access and crown preparations in diverse global practices.

Sirona's innovation legacy endures via Dentsply Sirona's 650+ R&D scientists and engineers, investing $150M+ annually—totaling $600M+ in six years—for advanced dental burs. The team drives developments like Midwest Once single-use diamond burs, enhancing infection control in polishing and milling tasks.

Best Products:

Carbide burs: Operative cutting for cavity preparation and gross reduction.

Diamond burs: Precision finishing for restorations and enameloplasty.

Surgical burs: Bone contouring in implant placements.

Milling burs: CAD/CAM fabrication for crowns and veneers.

Polishing burs: Surface smoothing in lab appliances.

Hager & Meisinger GmbH, commonly known as Meisinger, is a global leader in precision dental burs and rotary instruments, founded on June 15, 1888, by Artur Meisinger in Düsseldorf, Germany, as the Deutsch-Amerikanische Zahnborherfabrik (DAZF). Specializing as a dental burs supplier, the company merged with E. Hager & Co. in 1924 to form its current entity, headquartered in Neuss, Germany. With a subsidiary in Centennial, Colorado (established 2001), and distribution through over 600 partners in more than 100 countries, Meisinger produces 45 million instruments annually, including diamond burs, carbide burs, and polishers tailored for dental practices and laboratories. Its "Made in Germany" ethos drives a portfolio of 12,000+ products focused on high-precision rotary tools for restorative dentistry, implantology, and oral surgery.

Meisinger upholds rigorous standards as a trusted dental burs supplier, certified under EN ISO 13485:2016 for medical device quality management, MDSAP, EN ISO 9001, and FDA approval, ensuring compliance in implant and rotary instrument production. Over 137 years, it has pioneered precision engineering, manufacturing tolerances at feasibility limits, and sold more than two billion products worldwide. Recognized for innovation in bone management and digital dentistry, Meisinger collaborates with leading clinicians, earning acclaim at events like the European Association for Osseointegration.

With 130+ years as a dental burs supplier, Meisinger supports diverse applications from cavity preparation to crown finishing. Notable cases include the High Altitude Comprehensive Implant Symposium (HACIS), a "ski-and-learn" education program launched in 2011, now in its 14th year, training surgeons on bone augmentation using Meisinger burs. Partnerships like the Prep & Finishing Kit with Dr. James Klim demonstrate real-world efficacy in restorative workflows, while Cobra diamond burs have enhanced precision in global practices for efficient shaping and margin refinement.

Meisinger's 350-strong team, led by Managing Directors Dr. Burkard Höchst and Sebastian Voss since 1998, fosters innovation through R&D in Neuss. In the U.S., CEO Ethan Miller and Brand Ambassador Alex Miller drive North American growth. Innovations like modified-depth diamond burs with guide pins and OKTAGON® implants integrate advanced materials for reduced vibration and longevity, expanding into digital workflows and eco-friendly production.

Key Products and Services:

Dental Diamond Burs: for precise cutting, contouring, and finishing in restorative procedures.

Dental Carbide Burs: for cavity preparation, trimming, and crown removal.

Dental Polishers: for smoothing and polishing composite and ceramic restorations.

Dürr Dental SE, a premier German dental technology firm and trusted dental burs supplier, was founded in 1941 by brothers Karl and Wilhelm Dürr as a precision mechanics workshop in Stuttgart-Feuerbach. Headquartered in Bietigheim-Bissingen, the company now employs approximately 1,350 people worldwide, generating over €374 million in revenue in 2024 while serving clients in 174 countries. Specializing in system solutions for dental practices, it excels in practice supply, suction systems, diagnostic imaging, prophylaxis, and hygiene—particularly as a key provider of dental burs disinfection and rotary instruments maintenance products. Nearly all production occurs in Germany, ensuring premium quality for global dental professionals.

With over 80 years of excellence, Dürr Dental holds prestigious certifications like AEO (2010) and DQS quality standards, underscoring its commitment to reliability. Notable accolades include Germany's Innovation Champion 2025, Best Managed Company 2025, Kununu Top Company 2023, Entrepreneur of the Year 2021 for CEO Martin Dürrstein, and the 2014 Hidden Champion Award for Social Responsibility. These honors reflect its role in setting industry benchmarks for dental burs suppliers and hygiene innovations.

Dürr Dental's 80+ years of expertise span countless dental practices, from small clinics to large universities, with proven applications in caries detection via VistaProof systems and periodontal prophylaxis using Lunos tools—demonstrated in international clinical reports showing enhanced patient outcomes. A notable case involves TeamViewer AR integration for remote technical support, slashing resolution times for suction and imaging equipment worldwide, while studies affirm superior proximal caries detection with near-infrared technology compared to traditional bitewing radiography. As a dental burs supplier, its hygiene protocols have supported efficient reprocessing in high-volume labs.

Under CEO Martin Dürrstein's leadership—joined by the second-generation legacy of Rudolf Dürrstein and Walter Dürr—the 500-strong headquarters team drives R&D, blending family tradition with cutting-edge collaboration. Innovation thrives via an open idea-submission process, yielding AI-enhanced software, sustainable suction systems, and networked diagnostics showcased at IDS 2025. This customer-centric approach ensures rotary instruments and dental burs solutions evolve for safer, greener dentistry.

Key Products and Services:

Dental Burs Disinfectant: Virucidal cleaning for burs and milling cutters, with corrosion protection and 1-minute reaction time.

Rotary Instruments Hygiene Solution: Broad-spectrum disinfection for carbide and diamond tools, supporting lab and clinic reprocessing.

German suppliers lead the market in proprietary diamond-coating techniques and precision tungsten carbide production.

Their burs are used in:

Restorative dentistry

Endodontics

Oral surgery

Prosthetics

Implantology

CAD/CAM milling

This ensures versatility for global dental professionals.

Germany’s industrial base enables manufacturers to maintain consistency even in high-volume production.

German burs are widely available worldwide through distributors, enabling stable, long-term supply chains.

Many suppliers offer custom manufacturing, a major advantage for brands seeking private-label solutions.

With numerous reputable companies to choose from, buyers should consider the following checklist:

Diamond, carbide, or stainless steel—each suits different clinical procedures.

Ensure the burs match mechanisms used in your clinic or dental lab.

For example:

Endodontic access burs

Finishing burs for aesthetic restorations

Surgical burs for implant systems

Confirm CE, ISO 13485, and sterilization compliance.

Bulk orders often reduce cost for distributors.

German companies are generally strong here, but international buyers should evaluate shipping networks.

Evaluating these factors helps clinics and distributors select a supplier that balances performance, cost, and dependability.

Germany continues to set global benchmarks for dental tool engineering thanks to:

Continuous innovation in coating and material science

Strong emphasis on manufacturing accuracy

Strict quality control and regulatory standards

Experience serving both domestic clinics and international markets

Investments in sustainability and high-efficiency production

With these strengths, Germany remains a destination of choice for buyers seeking reliable and high-performance Dental Burs Suppliers.

As dental technology continues to advance, selecting a reliable supplier of dental burs is more important than ever. Germany’s top suppliers lead the market in precision, innovation, durability, and regulatory excellence. Their rotary instruments deliver superior performance across a wide variety of clinical procedures, making them trusted partners for dentists, distributors, and dental laboratories around the world.

This guide has outlined the key factors that define the best Dental Burs Suppliers in Germany and introduced the leading brands to watch in 2025. Whether you're sourcing for a clinic, a retail distribution network, or OEM manufacturing, Germany remains one of the most dependable markets for dental burs.